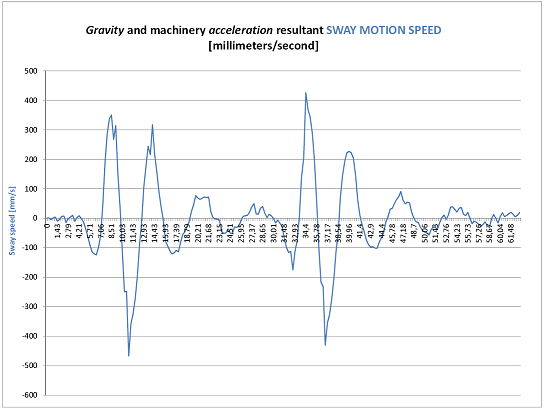

Sway motion under gravitation force

Painovoiman alainen taakan heilahdusliike

Optic motion detection

Picture 1:Typical material handling remote body sway motion in mm/s under ANTI-SWAY motion control.

Please notice that sway speed is not material transfer speed.

Here measured real motion speed is body [114] speed from load carrier observer's [101] point of view.

Optic motion detect is the fastest way to measure positions, controlability will improve with time

X-axis time [s], Y-axis motion speed [mm/s]

|

Technology is usable for moving bodies from nano to macro level because of its optical interface and control timer resolution.

If moving body is pictureable with visual or unvisual light and motion control exist, closed loop motion control is possible.

|

Closed loop visual motion speed detection measures two points [112] visual information between known time intervals.

Calculated motion speed is observer view of motion between observer [101] and interesting object [114].

With two or more observers detecting same object's motion, observers will receive motion axis relevant motion control data.

To syncronize observers measurement results, we need agreement between observers about simultaneity.

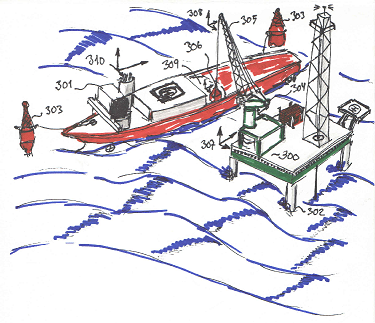

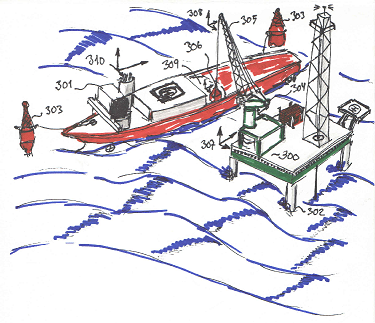

Picture 2:Several bodies and motion detection

At North Sea lifting work is only allowed only under wind speed of 6 m/s.

If we have bodies [300,301] that have unprictable motions and own coordinates [307,310],

how to use optical motion control without any cable?

This tehnology proposal is developed to increase working safety and productivity.

|

Drilling rig [300] and a service vessel [301] meetting at the North Sea.

|

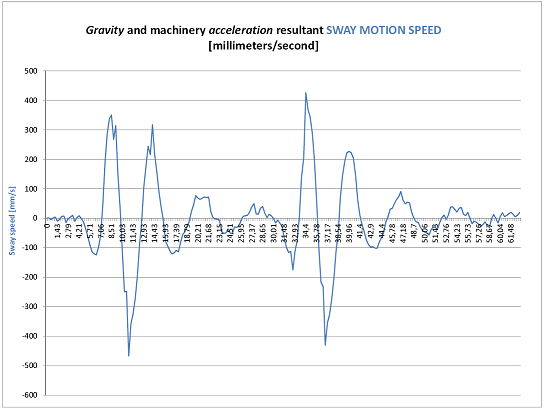

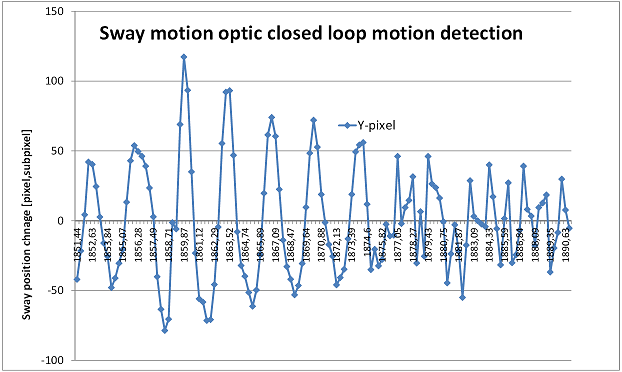

Picture 3:Sway motion detection related optical results

When sway motion is uncontrolled, the user must make corrections by himself.

Because basicly all systems act differently.

Automated motion control helps in many ways but especially when working enviroment include turbulence.

Then we have more time to observe more important incidents than only to detect and

control manually gravity and acceleration dependent sway motion.

X-axis time [s], Y-axis motion image ROI (Region of interest) pixel change [pixel,subpixels]

|

Harmonic sway motion keep on swaying until sway energy will be end or control system (automated or human) makes correction movement.

Required correction movement need precollected accurate data about sway speed and direction.

|